Thanks Rich and Hans, I was hoping that it would be simple, but of course, what is? Now I have to go and rescue the damn thing and remove the loom...

I really have to write up some of the stuff I have done to her: mostly tales of how much rust you can get in a rustproof car combined with a litany of 'money saving' bodges that I have had to unbodge, potentially lethal neglect and more rust...

For example:

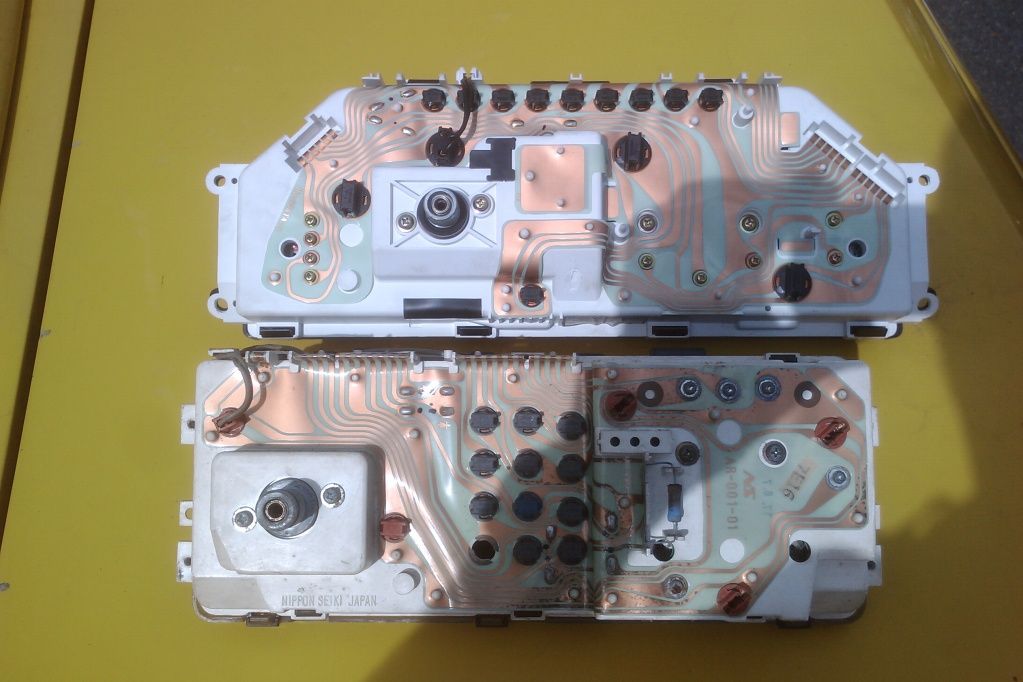

I enjoy wreck diving and, frankly, parts like this look like they came from this Beaufighter

rather than the cabin of a Midas

The bottom line is that the car that it becomes increasingly clearly miraculously managed to not only drive to Stoneleigh but enjoy immensely was hanging together: for example: the 'rubber' disk under the steering column was badly torn and generally had the consistency of stringy marshmallow. Fortunately, this rather effectively camouflaged the fact that the pinch bolt underneath was chillingly loose. All of this I was utterly oblivious to, which is hardly embarrassing at all. Any lack of response to deflection of the wheel I was blaming on the uneven hydrogas setup...

As for the carburettor, I'm just

really lucky that I have Southern Carburettors on my doorstep and some very patient and extremely knowledgeable people who have negotiated me through the complex ways an SU can keep on working tolerably while sporting the needle from a one litre HLE!

After a rebuild, in which I discovered that the brass tipped needle valve was not only amusingly worn but that the sprung tail had literally drilled a neat hole through the point where it came into contact with the float, that the two grommets in the enrichment circuit were not really either round or rubbery any more while the gasket was neatly folded in half, I thought all would be well.

She ran horribly rich on the standard BDL jet so I tried the one from the HLE again and she ran like a rusty bicycle. After a lot of messing around she's running nicely across the board on a BCC. Quite why this is so on a standard carb manifold, standard Midas stainless exhaust and metro cast exhaust manifold I don't know, but that give me the right air to petrol ratio across the board (well, a tiny bit rich at Idle) and I've replaced or checked everything else so that looks to be the permanent solution.

I hope that's interesting,

Cheers chaps.